Analog PID controller

This scenario will allow you to control the state of the selected system.

A proportional integral derivative (PID) controller can control temperature, pressure, flow, and other process variables. As its name implies, a PID controller combines proportional control with additional integral and derivative adjustments, which help the unit automatically compensate for changes in the system.

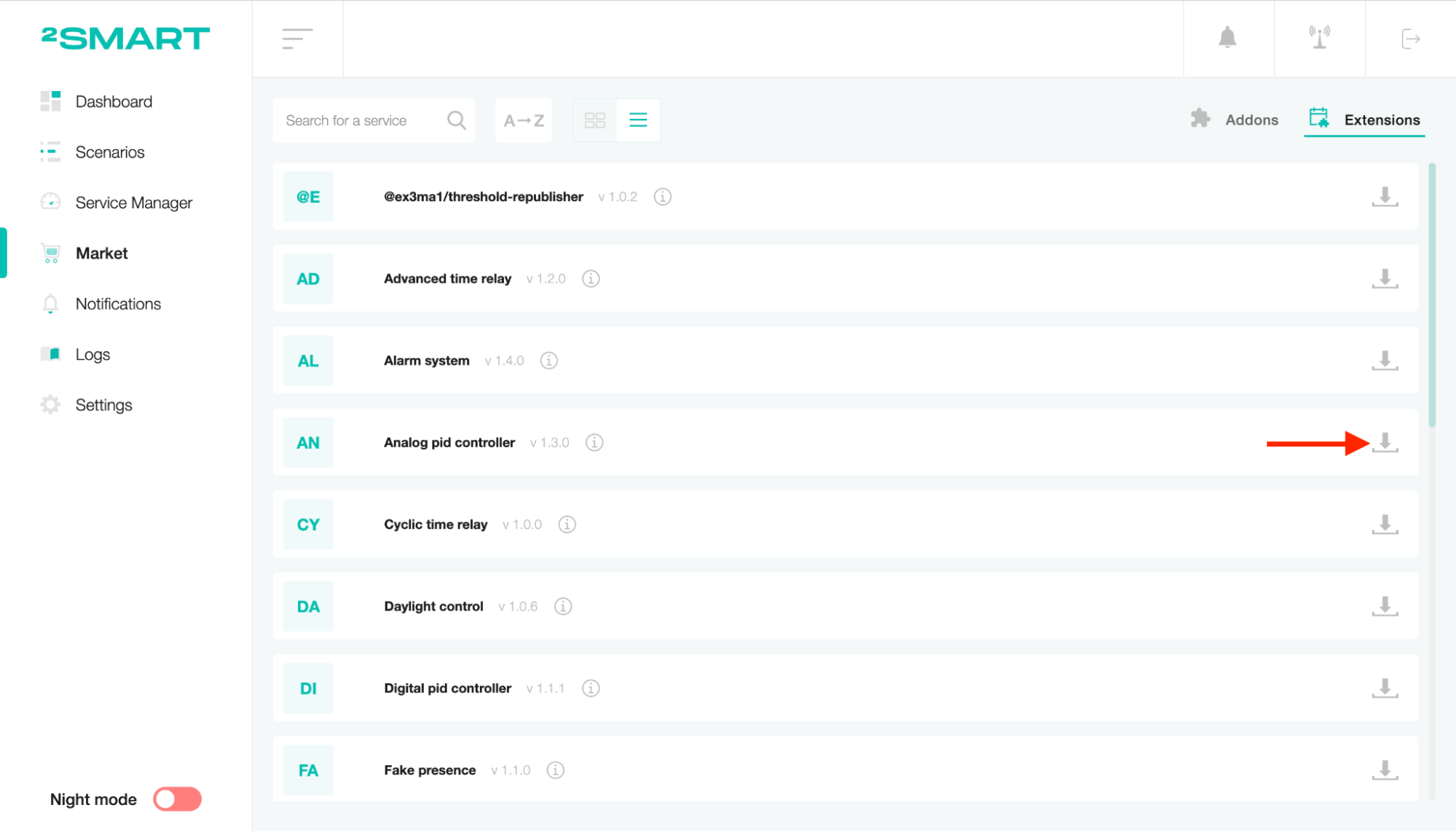

Installation

On the Market page, open the Extensions tab and click on the download icon near the selected item.

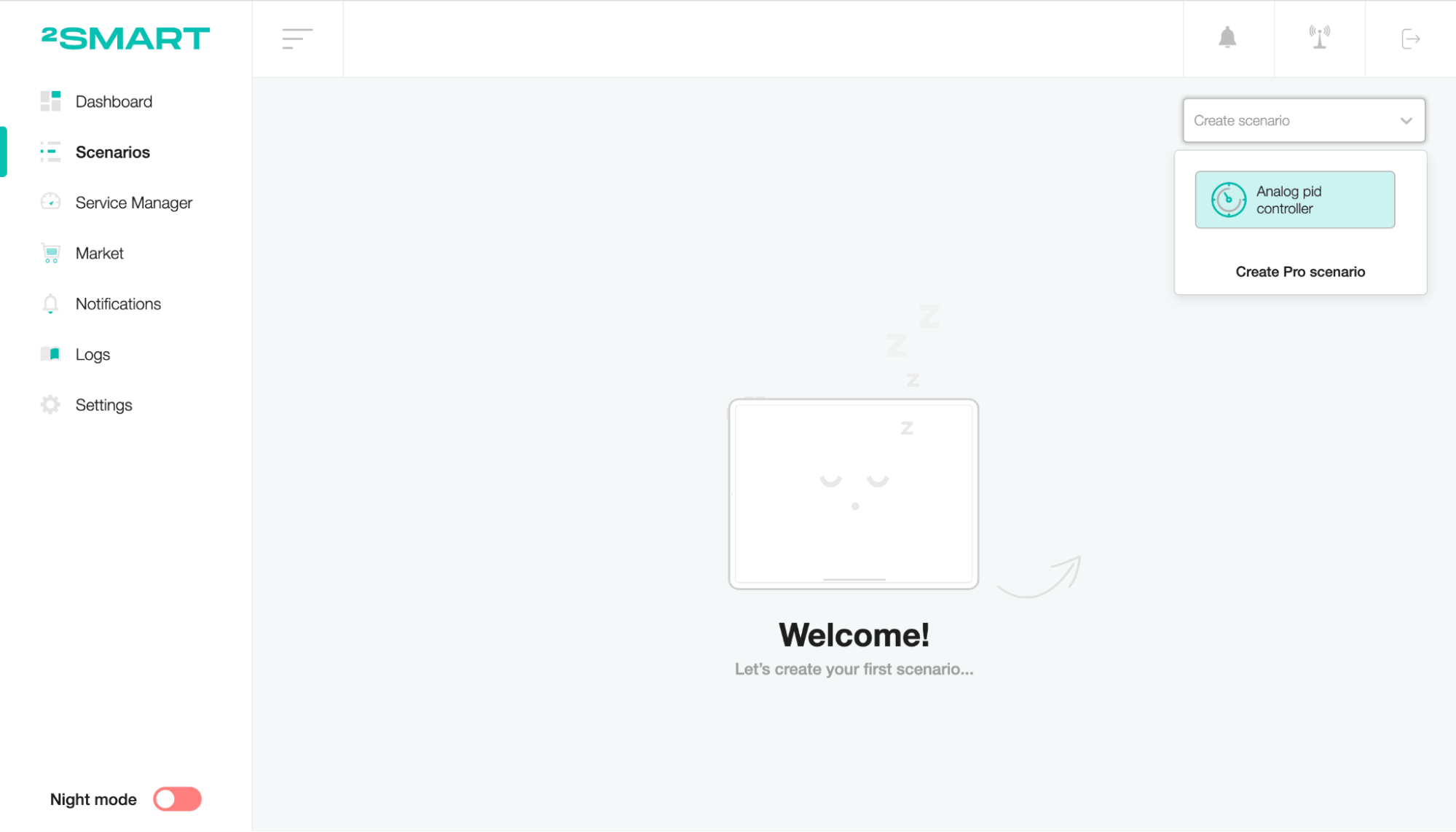

Go to the Scenarios page, click the “Create scenario” list and select the scenario you need.

Setup

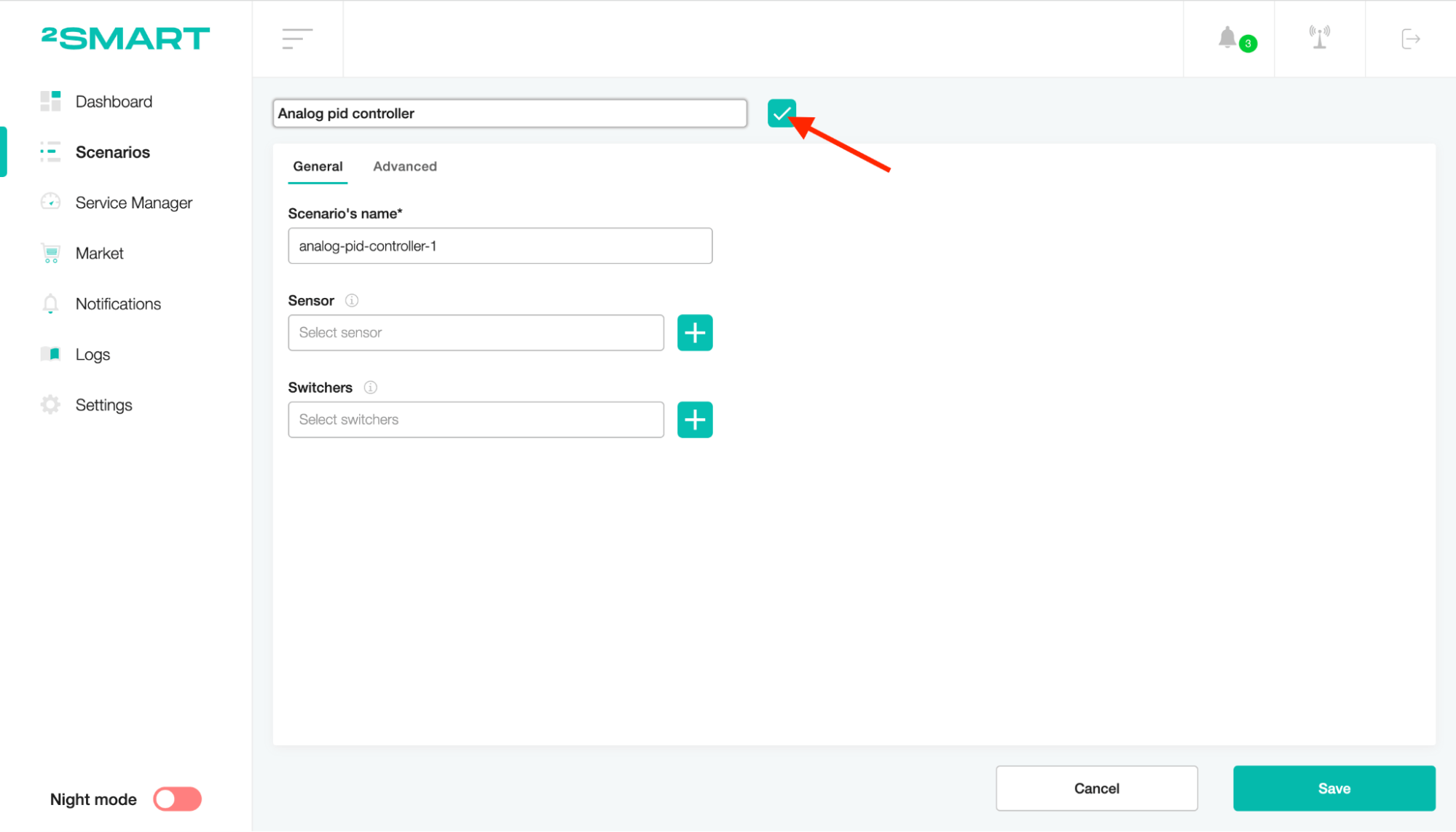

To edit the scenario name, click on the title, enter a new value and save.

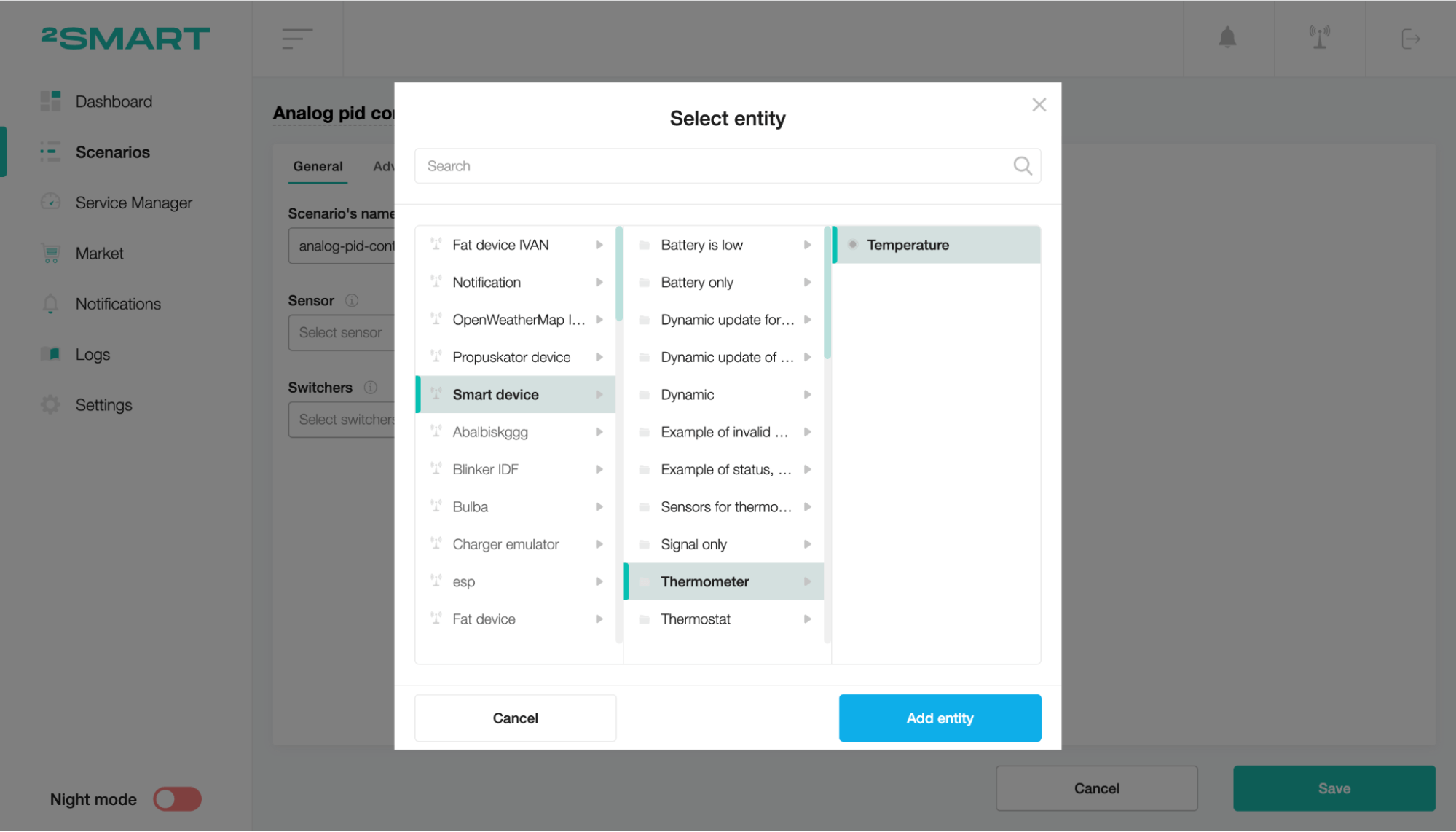

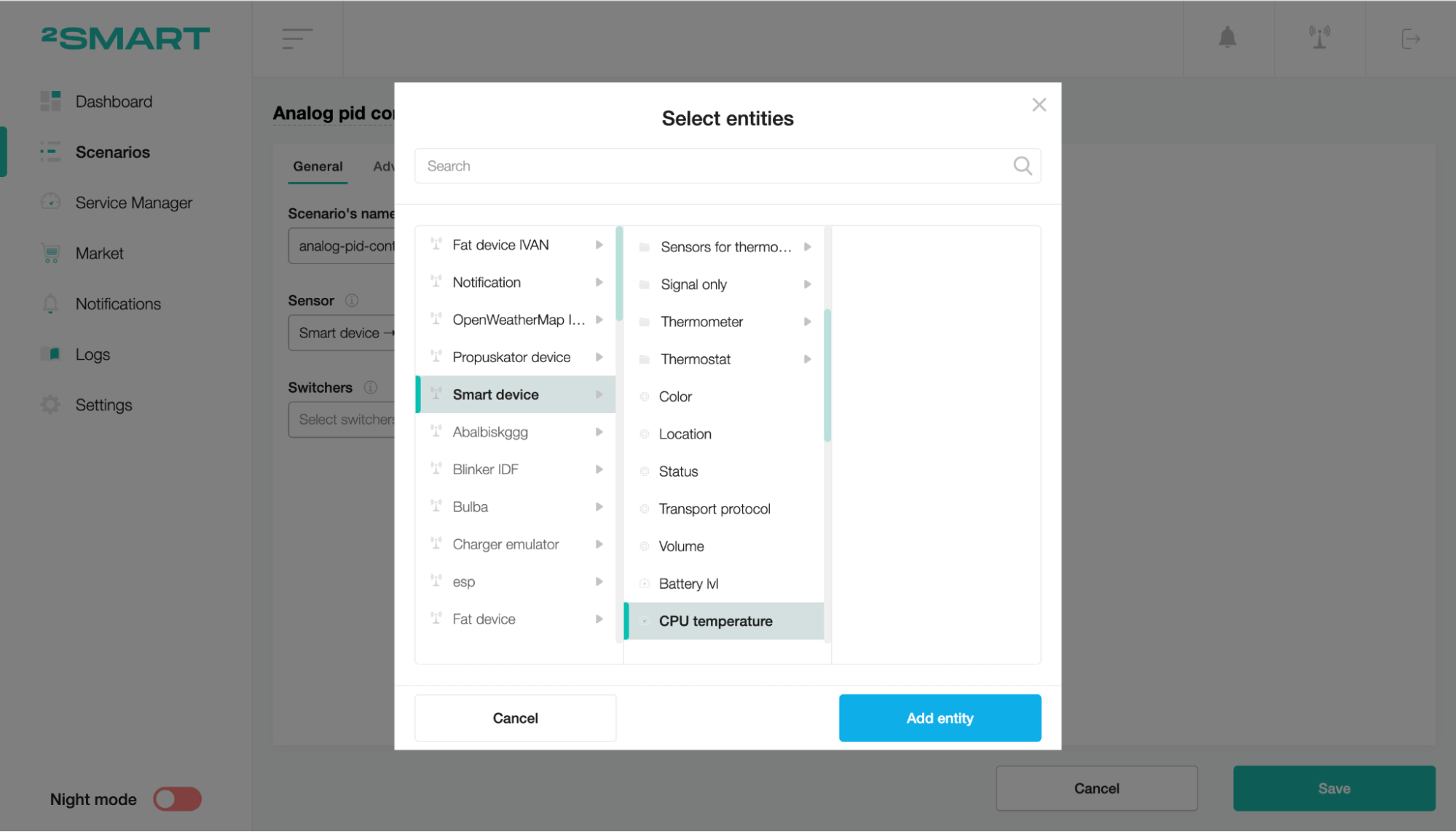

Choose the device sensor of the current system state.

Choose device sensors for monitoring system status.

The working principle of a PID controller is that the proportional, integral, and derivative terms must be individually adjusted or "tuned." A correction factor is calculated and applied to the input based on the difference between these values. For example, the heat will be increased if an oven is cooler than required. Here are the three steps:

Proportional tuning involves correcting a target proportional to the difference. Thus, the target value is never achieved because as the difference approaches zero, so too does the applied correction.

Integral tuning attempts to remedy this by effectively cumulating the error result from the "P" action to increase the correction factor. For example, if the oven remained below temperature, "I" would act to increase the head delivered. However, rather than stop heating when the target is reached, "I" attempts to drive the cumulative error to zero, resulting in an overshoot.

Derivative tuning attempts to minimize this overshoot by slowing the correction factor applied as the target is approached.

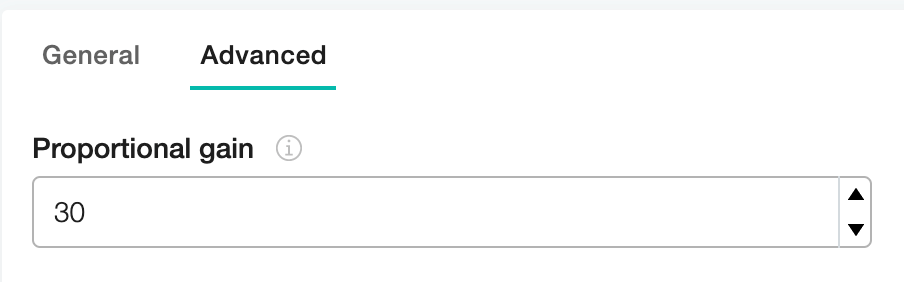

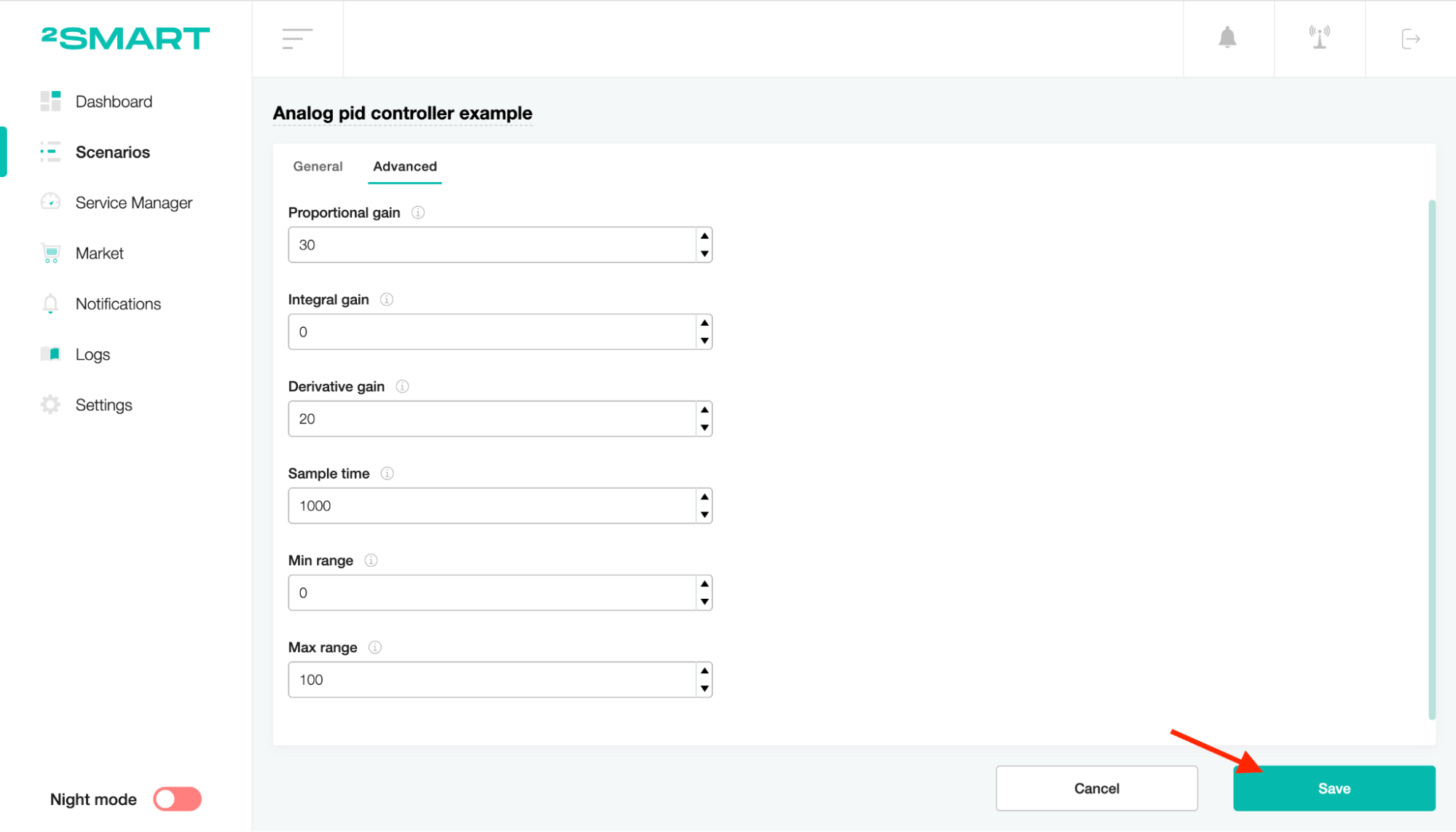

For the correct operation of the scenario, it is necessary to select and calibrate these coefficients. On the Advanced tab, set the correction for the current deviation (example: 5).

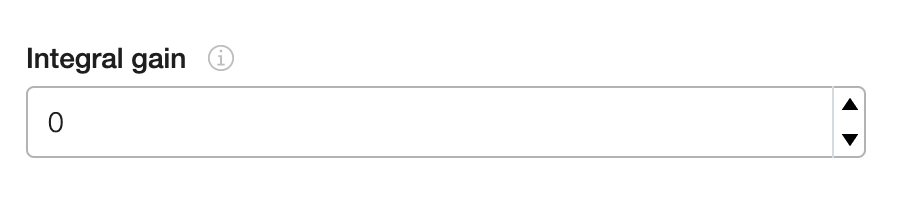

Set the correction for the previous abnormality (example: 5).

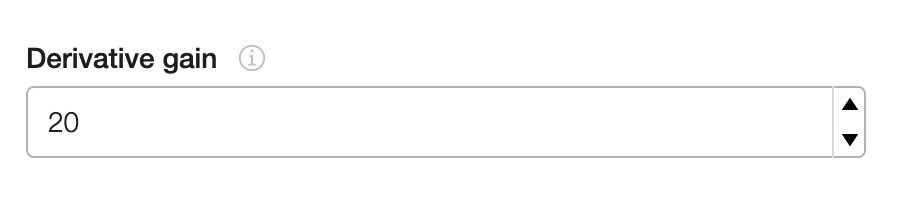

Set the predicted variance correction (example: 5).

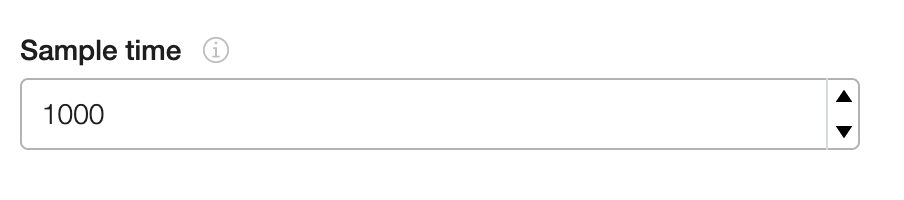

Set the minimum interval (in ms) between adjustments (example: 50).

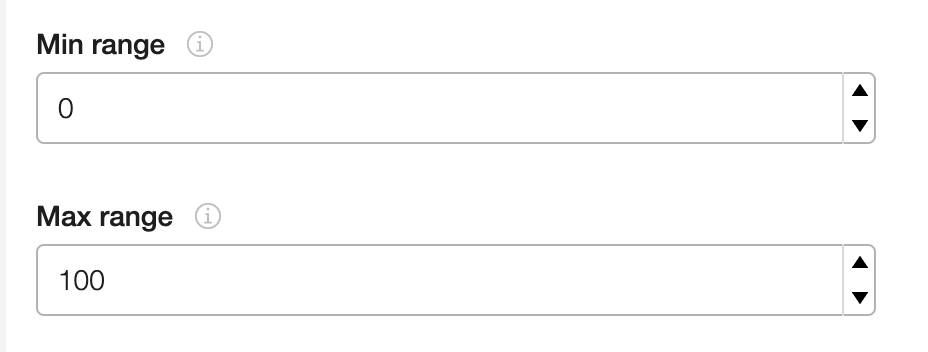

Enter the minimum and maximum values that the scenario can set (example: 0 and 100).

To save the scenario, click the “Save” button.

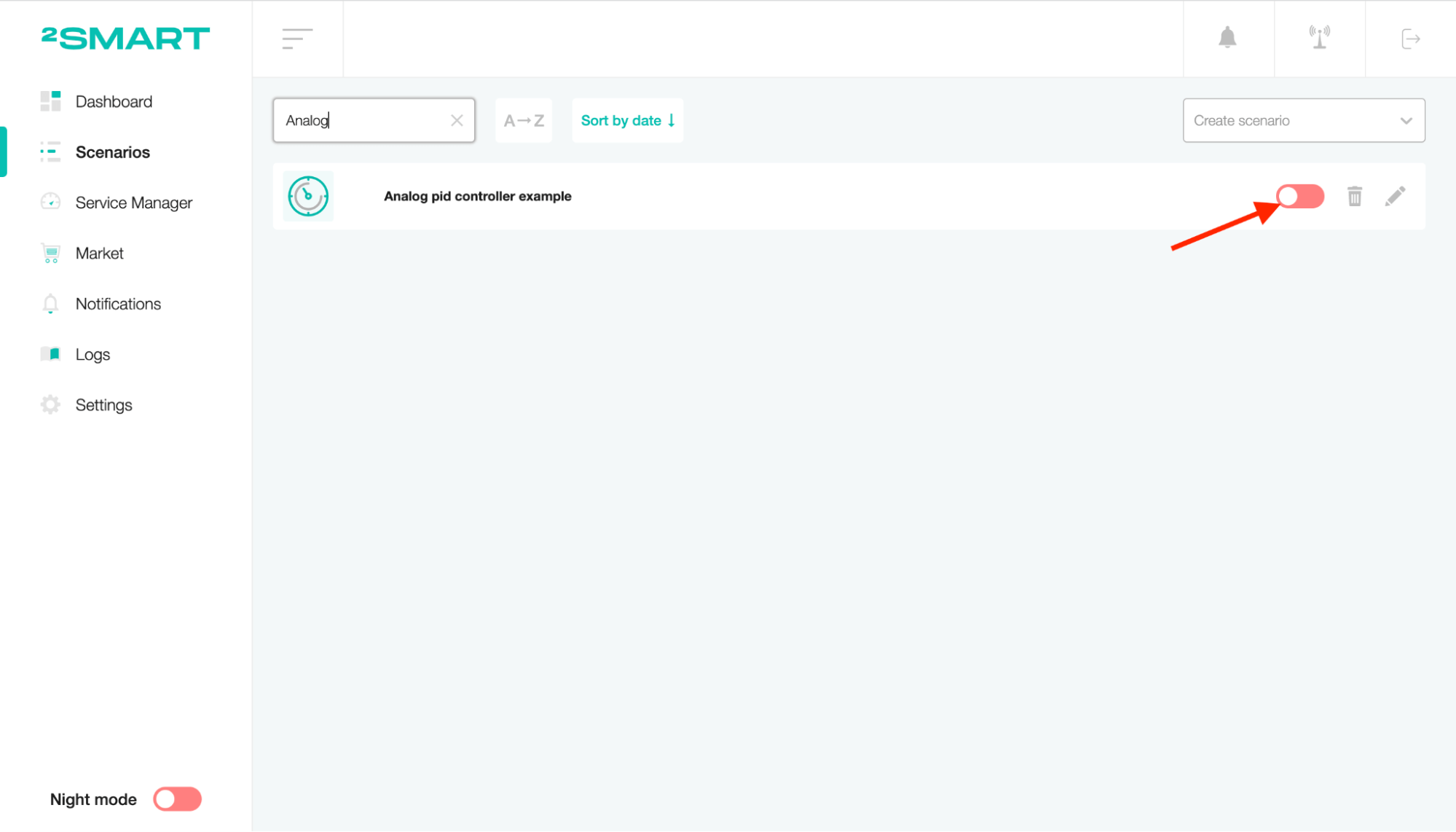

To start the scenario, turn on the toggle of the status.

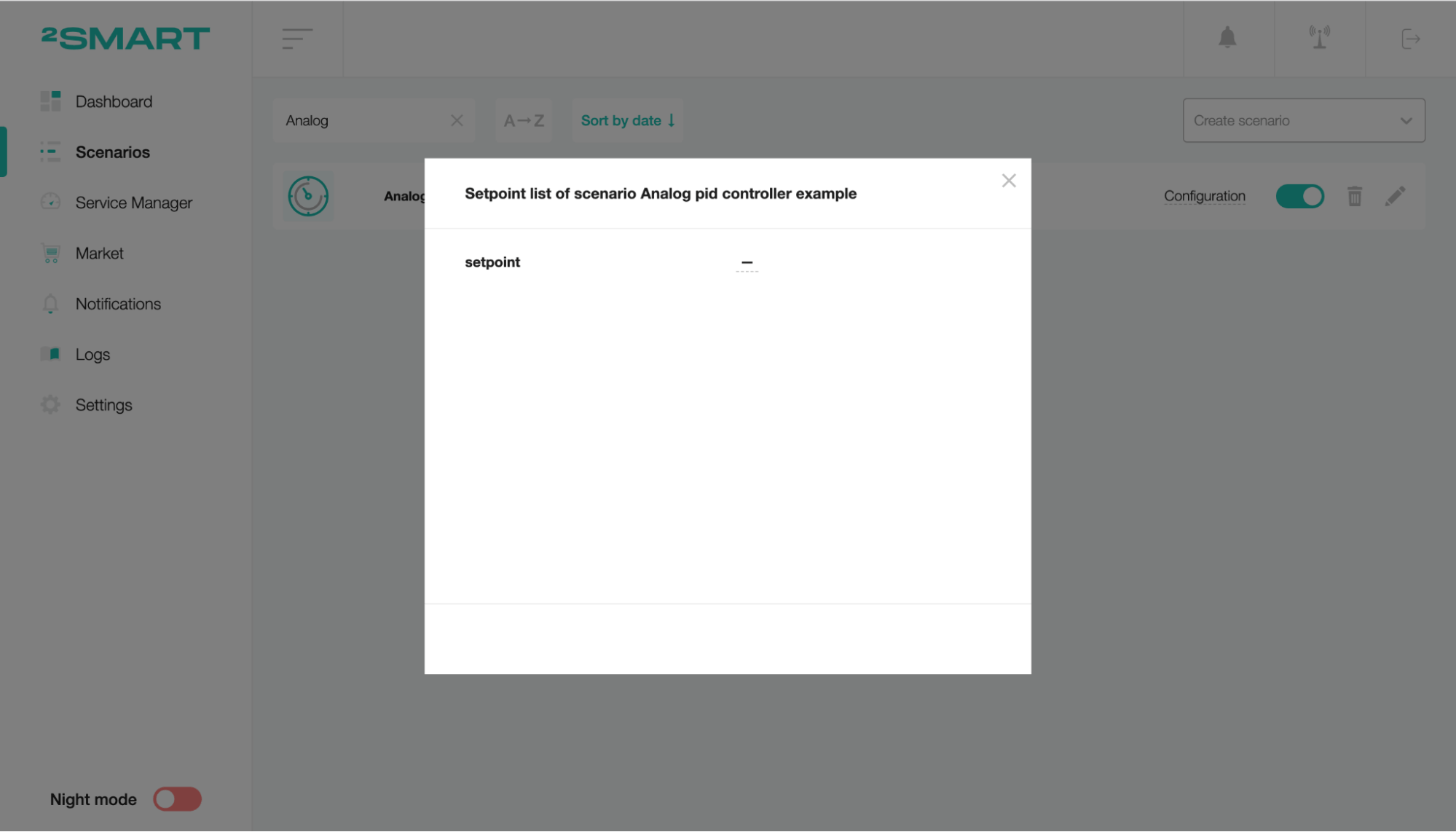

Turn on the scenario, and the threshold will appear in the scenario settings. Click on it to see the details.

As an example, enter the setpoint temperature to support the device's condition.

An analog PID controller eliminates the cycling associated with on-off control. This controller decreases the average power supplied to the heater as the temperature approaches the setpoint. This slows down the heater so that it will not overshoot the setpoint but will approach the setpoint and maintain a stable temperature. This proportioning action can be accomplished by turning the output on and off for short intervals. This "time proportioning" varies the ratio of "on" time to "off" time to control the temperature.